What Purpose Does the Assembly Line Serve?

Are you ready to uncover the hidden gears of efficiency?

Step into the world of the assembly line, where productivity soars and industries transform.

Brace yourself for a revolution in manufacturing as we explore the purpose and power of this ingenious system.

From streamlining production to driving profitability, the assembly line holds the key to unlocking untapped potential.

Join us on this journey as we unravel the intricate web of benefits that awaits those who embrace this game-changing innovation.

The Efficiency Boost: How the Assembly Line Streamlines Production

The assembly line can significantly increase productivity and streamline production processes. By implementing an assembly line, companies can achieve higher output rates and improved efficiency in their manufacturing operations.

The assembly line allows for the division of labor, where each worker is assigned a specific task, resulting in a more specialized and efficient workforce. This specialization reduces the time required for workers to switch between different tasks, minimizing downtime and maximizing production.

Additionally, the assembly line enables a continuous flow of materials, as each worker completes their assigned task and passes the product onto the next worker. This eliminates the need for workers to search for materials, reducing delays and interruptions in the production process.

Overall, the assembly line provides a systematic and efficient approach to manufacturing, leading to increased productivity and streamlined production.

Increased Productivity: The Impact of the Assembly Line on Manufacturing Output

You can see how the assembly line has significantly boosted manufacturing output. With the implementation of this innovative production method, factories have experienced a dramatic increase in productivity. Here’s why:

– **Efficiency:** By dividing the manufacturing process into smaller tasks, workers can focus on specific tasks, leading to improved efficiency and reduced time wastage.

– **Specialization:** The assembly line allows workers to specialize in one task, enabling them to become highly skilled and proficient in their area of expertise.

– **Standardization:** Standardized processes and equipment on the assembly line ensure consistent quality and reduce errors, resulting in higher output and customer satisfaction.

Overall, the assembly line not only streamlines production but also fosters a sense of belonging among workers. By working together in a synchronized manner, employees feel a sense of unity and achievement, contributing to a positive work environment and ultimately, increased manufacturing output.

Driving Profitability: The Financial Benefits of Implementing an Assembly Line

Implementing an assembly line can drive profitability by increasing efficiency, reducing costs, and maximizing output. By streamlining the production process, tasks are divided and assigned to specialized workers, resulting in higher productivity. This allows for faster production and shorter lead times, enabling businesses to meet customer demands more efficiently.

Additionally, the assembly line reduces labor costs by eliminating unnecessary steps and minimizing the need for skilled workers, thus lowering overall production expenses. With the ability to produce more goods in a shorter period, businesses can take advantage of economies of scale, reducing unit costs and increasing profit margins.

Transforming Industries: The Revolutionary Impact of the Assembly Line

Revolutionizing industries, the assembly line has transformed manufacturing processes and revolutionized the way products are made. This groundbreaking method of production has had a profound impact on various sectors, driving efficiency and productivity to new heights.

Here are three key ways the assembly line has revolutionized industries:

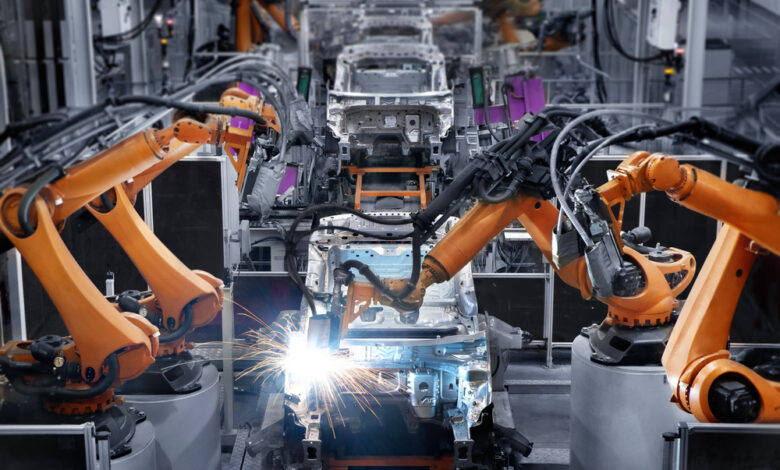

– Increased production speed: By dividing tasks into smaller, specialized ones and using automated machinery, the assembly line has significantly accelerated the manufacturing process. This allows for the production of a greater quantity of products in a shorter amount of time.

– Improved quality control: The assembly line enables a systematic approach to manufacturing, reducing errors and defects. Through standardized processes and rigorous quality checks, companies can ensure that each product meets or exceeds the required standards.

– Enhanced cost-effectiveness: By streamlining production and reducing the time and resources spent on each product, the assembly line has led to cost savings for businesses. This has made products more affordable and accessible to a wider range of consumers, contributing to the growth and expansion of industries.

Considering these transformative benefits, it’s no wonder that the assembly line has become a cornerstone of modern manufacturing, reshaping industries and providing a sense of belonging to those involved in the production process.

Conclusion

In conclusion, the assembly line serves as a game-changer in the manufacturing industry. With its ability to streamline production, increase productivity, and drive profitability, it has revolutionized the way industries operate.

Implementing an assembly line has proven to be a financial boon for companies, allowing them to efficiently meet the demands of consumers.

It’s safe to say that the assembly line has truly transformed the manufacturing landscape, propelling industries forward at breakneck speed.

So, buckle up and enjoy the ride! And if you are looking for a manufacturer of change parts, click the link!